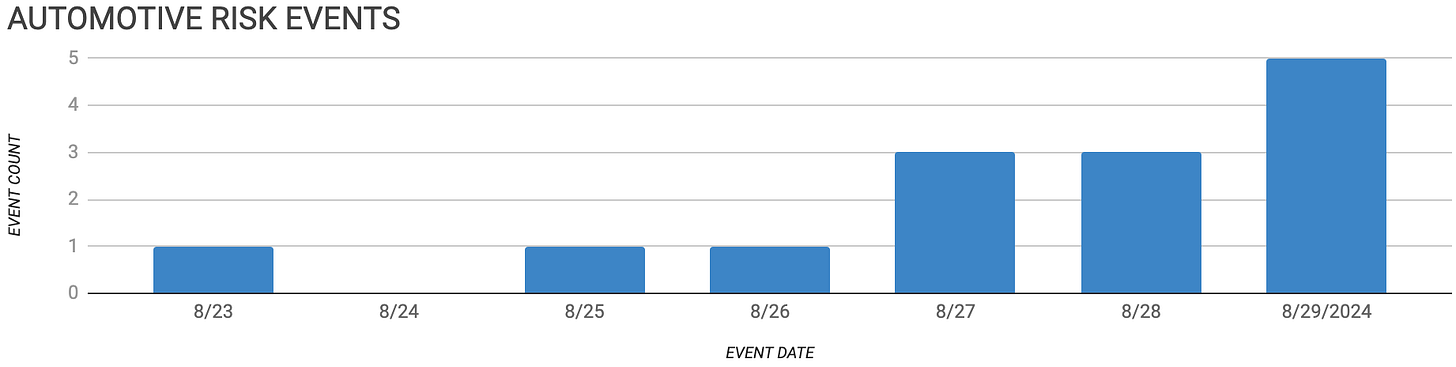

Automotive Supply Chain Risk Digest #395

August 23 - 29, 202, by Elm Analytics

Contents

Polestar appoints new CEO amid SUV launches.

GM hires ex-Apple exec for software.

Typhoon Shanshan disrupts Japan's automotive industry.

Mercedes EV fire shakes South Korea's confidence.

Fire damages Rivian EVs in Illinois.

CAR explores USDOT's V2X road safety potential.

GM faces class action over faulty transmissions.

Piston Group retains minority certification status.

Toyota's global production down slightly for sixth month.

GM delays Indiana battery plant production start.

Canada imposes 100% tariff on Chinese EVs.

Potential semiconductor shortage threatens automotive production.

Panama Canal lifts draft and transit restrictions.

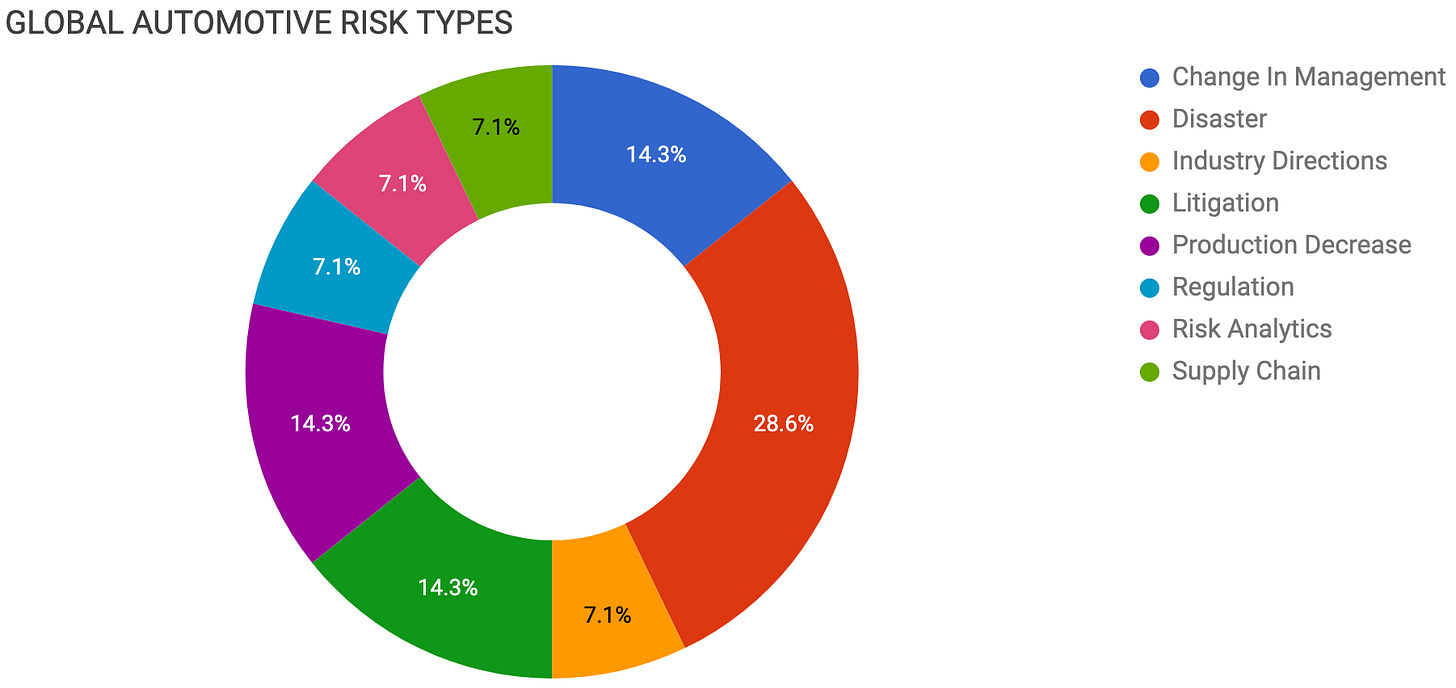

Change In Management

Polestar has appointed Michael Lohscheller as its new CEO, replacing Thomas Ingenlath. This change comes as the company launches two new electric SUVs to compete in the premium segment.

Although Lohscheller brings significant industry experience, his appointment during a critical period introduces potential risks for Polestar as it works to meet market expectations amidst a broader slowdown in EV demand.

Leadership changes during major product launches can affect strategic direction and operational stability, underscoring the importance of managing this transition effectively in the competitive EV market.

General Motors has named Tim Twerdahl $, a former Apple executive, as vice president of product management for its software services unit.

Twerdahl, who previously oversaw products like AirPods and Apple TV at Apple, will be reporting to Baris Cetinok, GM's senior VP of software and services product management.

This decision reflects GM's ongoing effort to bolster its software expertise and compete in autonomous and electric vehicle development against companies like Tesla.

Disaster

Typhoon Shanshan has disrupted Japan's automotive industry, forcing major automakers like Toyota, Nissan, and Honda to suspend operations at multiple domestic plants due to safety concerns.

The storm's powerful winds and heavy rains have raised the risk of flooding and landslides, affecting critical manufacturing and supply chain operations.

Semiconductor companies, such as Renesas and Tokyo Electron, which supply essential components to automakers, also halted production, further impacting the industry.

The shutdowns come at a challenging time for automakers already grappling with global supply chain issues and EV demand fluctuations. Travel disruptions have compounded the problem, with cancellations of flights and suspension of crucial rail services, including the bullet train, making it difficult for employees and goods to move efficiently.

The typhoon underscores the urgent need for resilience planning in the face of increasingly frequent extreme weather events, a crucial step to ensure the industry's future stability.

→ Japan Meteorological Agency: Tropical Cyclone Map / Tracking

A recent fire involving a Mercedes-Benz electric sedan in an underground parking lot in Incheon, South Korea, has shaken consumer confidence in electric vehicles, threatening the country's aggressive push toward EV adoption.

The blaze, which damaged nearly 900 cars and took over eight hours to extinguish, has led to increased concerns over the safety of EVs despite their lower overall fire risk compared to gasoline-powered vehicles.

In response, listings of secondhand EVs have surged as worried owners seek to sell their cars.

The government and automakers, including Mercedes-Benz, are taking steps to reassure the public, with plans to cap EV charging to 90% in residential parking areas and require disclosure of battery suppliers.

Addressing these safety concerns is critical to restoring consumer confidence and ensuring the success of South Korea's ambitious EV transition.

A fire broke out in the parking lot of Rivian's Normal, Illinois, plant on Saturday night, damaging an unspecified number of EVs. The Normal Fire Department responded to the incident, and the fire was extinguished by midnight, with no injuries reported.

Rivian confirmed that the fire did not affect the EV assembly plant itself. The fire's cause is under investigation, according to Rivian spokesperson Kelli Felker and Normal Fire Department spokesperson Matt Swaney.

Industry Directions

The Center for Automotive Research (CAR) takes a deep dive into USDOT's V2X initiative and its potential to revolutionize road safety and connectivity.

Litigation

General Motors has been ordered by a federal appeals court to face a class action over knowingly selling hundreds of thousands of vehicles with faulty transmissions. The court ruled that a lower court judge had the discretion to allow drivers to sue in groups over 514k Cadillac, Chevrolet, and GMC vehicles equipped with problematic eight-speed automatic transmissions.

Piston Group, one of the largest Black-owned automotive suppliers, has won a significant legal battle against the Michigan Minority Supplier Development Council (MMSDC). A judge ruled that the MMSDC wrongfully revoked Piston Group's minority business enterprise status. The decision grants Piston Group a permanent injunction to retain its minority certification.

Production Decrease

Toyota reported a 1% decline in global production for July, marking the sixth consecutive month of reduced output, primarily impacted by decreased production in China and Thailand, which fell by 6% and 13%, respectively.

US sales dropped 5%, attributed to fewer sales days and airbag issues that halted the production and delivery of the Grand Highlander and Lexus TX SUVs.

In China, Toyota continues to face challenges from the increasing popularity of NEVs produced by domestic Chinese brands.

Despite these setbacks, the drop in output was smaller compared to June's double-digit decrease.

General Motors has announced a one-year delay in the start of production at its New Carlisle, Indiana, battery plant, pushing the timeline from 2026 to 2027.

Despite the delay, construction will continue as planned. GM attributes the postponement to contract negotiations and current market conditions, including lower-than-expected consumer demand for EVs.

Local officials, including Jeff Rea of the South Bend Regional Chamber, believe the delay provides an opportunity to complete necessary infrastructure work around the plant site.

The plant, a joint venture with Samsung SDI, is expected to employ around 1.6k people upon completion. Automakers face challenges balancing significant investments in EV infrastructure with fluctuating market demand, impacting the automotive supply chain and regional economic development.

Regulation

Canada will impose a 100% tariff on Chinese electric vehicles starting October 1, aligning its policy with the United States and European Union.

Prime Minister Justin Trudeau announced the move to protect domestic car production and support the growing investments in electric vehicle and battery factories in Canada.

The new tariffs have raised concerns about potential Chinese retaliation. Environmental groups argue that such high tariffs could limit EVs' affordability and slow the transition to zero-emission vehicles.

Despite these concerns, the Canadian government views the tariffs as necessary to counteract China's trade practices and support local industries.

These tariffs could reshape the landscape for electric vehicle imports in Canada, affecting pricing, competition, and the pace of EV adoption while potentially escalating trade tensions with China.

Risk Analytics

Deja Vu? The automotive industry could face significant challenges due to a potential semiconductor shortage anticipated in late 2025 or 2026, particularly for mature nodes of 40 nanometers and above.

S&P Global Mobility highlights that while investments focus on advanced chip technologies, mature nodes remain crucial for automotive applications, such as microcontrollers and power management systems.

A surge in new battery-electric vehicle launches and low inventory levels may strain supply chains.

Additionally, rising demand from other sectors, such as consumer electronics, could push automotive manufacturers to the back of the supply queue, echoing the shortages experienced in 2020.

This potential shortage could have a profound impact, impeding automotive production and delaying the rollout of new vehicle models.

The anticipated semiconductor shortage could disrupt automotive production and hinder the industry's shift towards electric vehicles, highlighting the importance of strategic planning and diversified chip sourcing to maintain stability.

Supply Chain

The Panama Canal Authority is lifting restrictions on vessel drafts and transit limits imposed due to drought, thanks to recent rains that have normalized water levels. The draft limit has been increased to 50 feet, and daily transits will rise to 36 vessels.

These changes are expected to significantly impact global shipping, especially routes from Northeast Asia to the US East Coast, which were severely affected by last year's El Niño-induced drought.

Ricaurte Vasquez, the canal administrator, indicated that while full recovery could take five to six months, the authority is planning for future droughts, potentially implementing seasonal restrictions.

I'm not sure the EV market is truly slower than anticipated. Perhaps it is more likely over-anticipated by company execs?

As ever, this an essential read. Looking forward to tomorrows update.