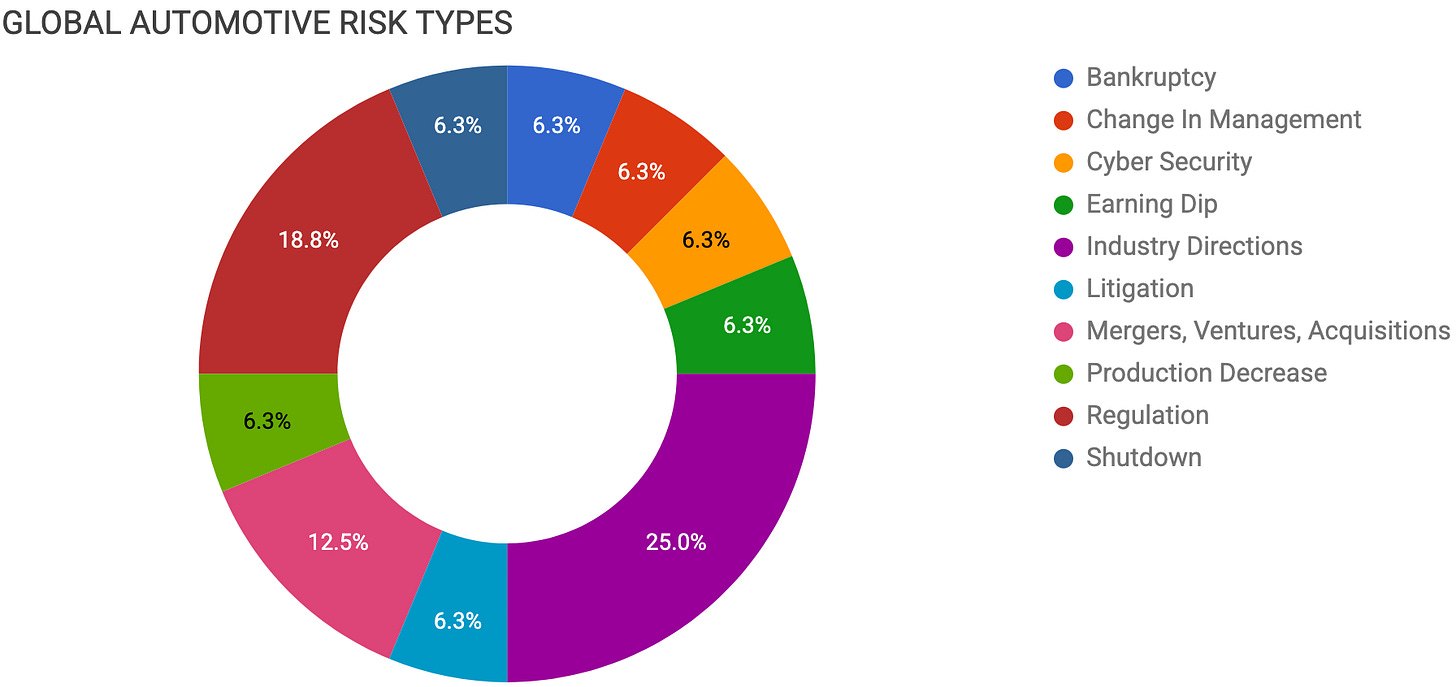

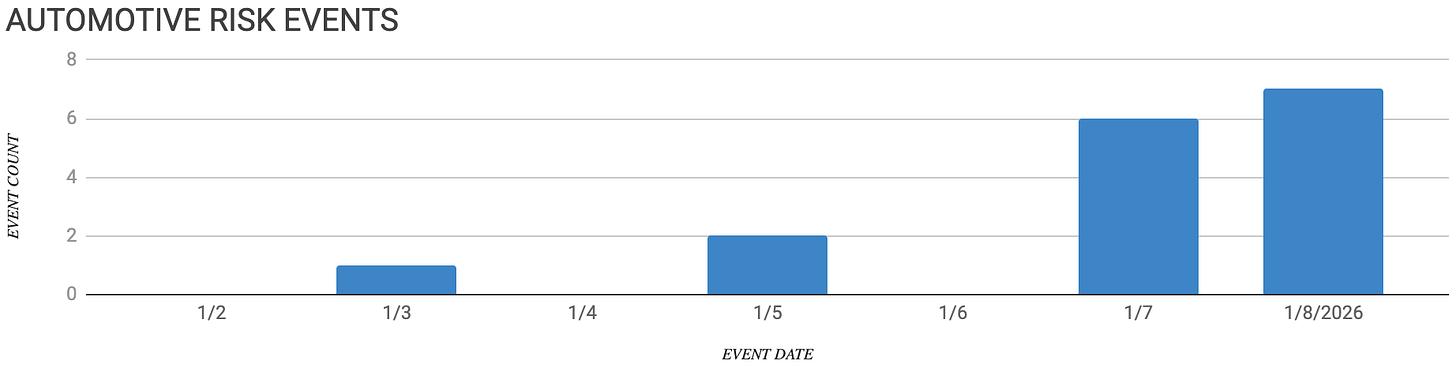

Automotive Supply Chain Risk Digest #464

January 2 - 8, 2026, by Elm Analytics

Contents

BANKRUPTCY

First Brands nears cash depletion

CHANGE IN MANAGEMENT

Former CEO named Volvo design chief

CYBER SECURITY

Cyberattack cut JLR Q3 volumes 43%

EARNING DIP

GM books $6B EV loss

INDUSTRY DIRECTIONS

CES: automakers partner with tech

BMW India push boosts local sourcing

LITIGATION

Dutch hearing may probe Nexperia

MERGERS, VENTURES, ACQUISITIONS

Dongfeng explores Turkey production launch

SDV open-source alliance grows to 32

PRODUCTION DECREASE

Stellantis Italy output hits 1950s lows

REGULATION

China urges battery capacity discipline

China hints rare earth export curbs

Japan suppliers absorb US tariff costs

SHUTDOWN

Honda delays restart amid chip shortage

Bankruptcy

First Brands faces an imminent cash crisis, warning it could deplete its funds by the end of January, with just $190M of the $1.1B in bankruptcy financing remaining.

The company, which sells parts such as filters, wipers, brakes, and lighting systems, is urgently seeking additional funding and accelerating its asset sales.

While restructuring under Chapter 11 and investigating alleged invoice fraud linked to its former CEO, creditors remain uncertain about the company’s true value.

This escalating situation poses an immediate risk to its automotive customers and casts significant doubt on future ownership and financial stability.

Change In Management

Volvo appointed former Polestar CEO Thomas Ingenlath as design chief amid a broader management reset and turnaround push under returning CEO Hakan Samuelsson.

The shift, alongside tighter collaboration with Geely and imminent new-model launches, could change platform commonality and supplier sourcing decisions.

Cyber Security

JLR reported that its Q3-2025 wholesale volumes fell 43.3% due to prolonged production halts caused by cyberattacks.

Earning Dip

GM is taking a $6B earnings charge after pulling back on EV plans, primarily to settle canceled supplier contracts.

These cancellations result from regulatory rollbacks that weakened earlier assumptions about EV demand.

The move highlights increased supplier and financial risk when manufacturers reverse capital-intensive strategies mid-cycle.

Industry Directions

CES 2026 underscored a broad shift by automakers and suppliers toward partnerships with tech companies to accelerate the development of software-defined vehicles, AI, and autonomy.

Executives said earlier attempts to build everything in-house drove fragmentation, higher costs, and slower deployment.

For supply chains, collaboration can ease financial strain and integration risk, but it also tightens interdependencies among OEMs, Tier 1s, and tech partners.

Automotive News:

BMW plans to launch 10 new models in India this year. To support this, the company also wants to increase local sourcing above its current 50%, which would help manage high import tariffs and boost luxury sales.

This strategy reflects a broader industry trend: as rising tariffs and tax differences push automakers to use more local parts and assemble in domestic markets, supply chains are becoming more fragmented.

As a result, companies are moving sourcing closer to their main markets to keep costs down and maintain demand.

Litigation

A Dutch court will hold a public hearing on 14 January to decide whether to open a formal investigation into alleged mismanagement at Nexperia.

In this case, the Dutch government has already invoked rare emergency powers to briefly take control of the company and to transfer Wingtech’s voting rights to a court‑appointed administrator.

This hearing is the first full airing of the dispute in open court.

It has become a test case for how Europe manages the risks associated with Chinese‑owned semiconductor assets under US export‑control pressure.

Extended legal and ownership uncertainty at Nexperia directly increases supply chain risk by threatening to prolong component constraints and triggering renewed, rolling production disruptions for OEMs and Tier 1 suppliers.

Mergers, Ventures, Acquisitions

Dongfeng’s Turkish distributor says the company is in talks with an investor to start making passenger cars in Turkey, with plans to begin production this year.

Although a final investment decision has not been made, the investor already has a facility ready.

Chinese automakers are looking to avoid extra Turkish taxes on cars imported from China and to benefit from Turkey’s access to the EU customs area.

Eclipse SDV and VDA have expanded their open-source automotive software collaboration to 32 companies, including OEMs, suppliers, semiconductor firms, and software providers.

The group is building a shared, automotive-grade software stack to reduce duplicated development work and speed up vehicle program launches.

For automotive supply chains, this approach could lower integration risk and cost volatility, while increasing systemic exposure to shared software dependencies.

Production Decrease

Stellantis’ Italian output dropped sharply in 2025 to levels last seen in the 1950s, driven by soft demand and delayed model launches.

The slump heightens ongoing volume and scheduling risks for Italy-based suppliers, despite hopes of a partial rebound in 2026.

Regulation

China’s industry ministry warned battery makers to optimize capacity and curb overcapacity risk, calling for tighter regulation of competition and stronger supervision across EV and energy storage batteries.

If China’s battery market tips into sustained oversupply, as in the solar sector, financial stress can ripple through, affecting manufacturers' health and destabilizing sourcing for global EV supply chains.

China has hinted it may restrict exports of rare earths to Japan under new dual-use controls, raising fears of supply disruption for EV motors and other automotive applications.

Japan has reduced but not eliminated its dependence on Chinese rare-earth materials and remains highly exposed to heavy rare-earth elements.

For automotive supply chains, even temporary controls could quickly constrain output and drive cost volatility across EV and electronics programs.

A Nikkei survey found that less than half of Japanese auto parts suppliers hit by higher US tariffs have managed to raise their prices.

As a result, many are absorbing the extra costs or looking for other ways to cope.

To address these challenges, some are moving production or investing more in the US to reduce the impact, while others are trying to become more efficient.

However, ongoing pressure on profit margins means weaker suppliers may have to cut capacity, delay investments, or leave certain programs.

Shutdown

Honda’s three GAC Honda plants in China have delayed reopening several times due to semiconductor shortages.

The latest restart date was moved from January 5 to January 19, extending shutdowns that started in late December.

Honda also stopped production in Japan for two days, January 5 and 6, after its key supplier, Nexperia, paused shipments. The company is seeking additional suppliers to maintain stable production.

Since late October, Honda has reduced North American output of some main models and now expects the chip shortage to lower operating profit by about $954M for the fiscal year ending March 2026.