Automotive Supply Chain Risk Digest #452

October 10 - 16, 2025, by Elm Analytics

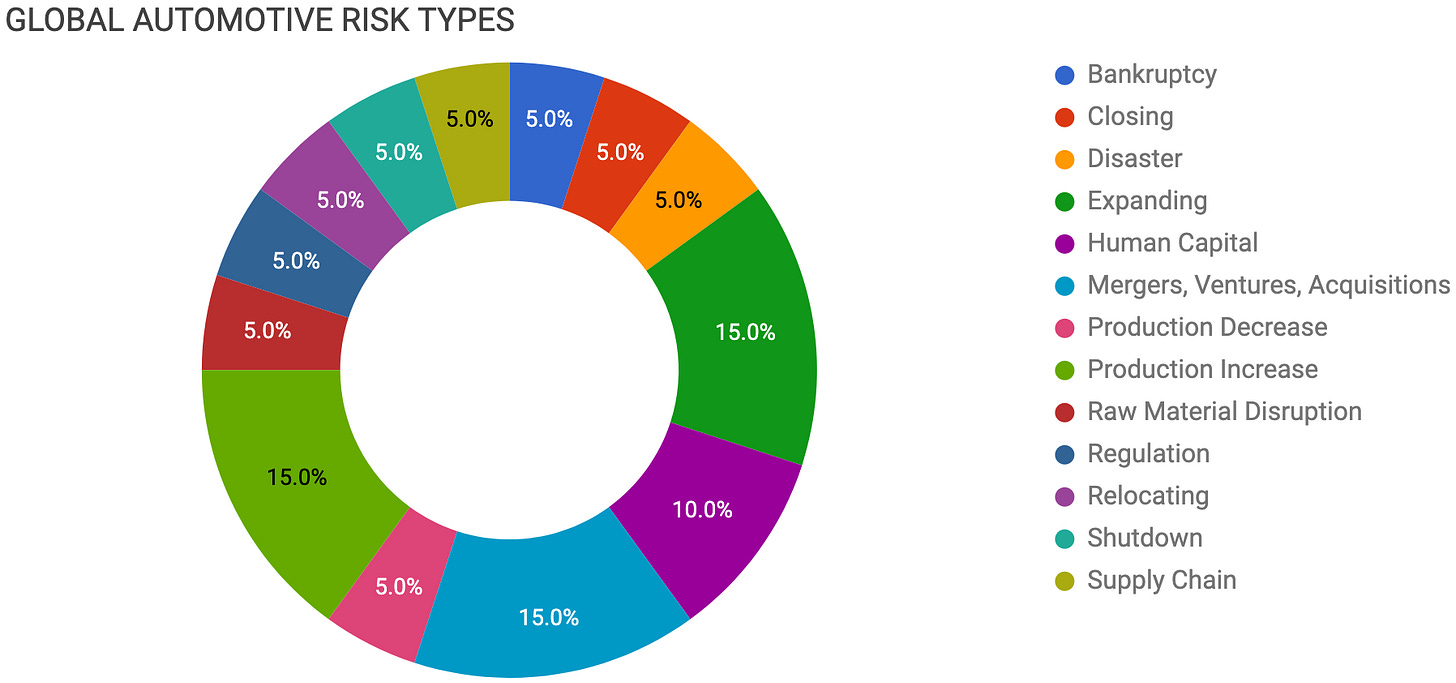

Contents

BANKRUPTCY

US watchdog seeks First Brands probe

CLOSING

Europe may shut eight auto plants

DISASTER

Novelis fire disrupts aluminum supply

EXPANDING

Stellantis boosts US plant investment

Kia expands Slovakia EV production

Judd Wire opens Mexico cable line

HUMAN CAPITAL

Webasto cuts 300 German admin jobs

GM extends Detroit Factory Zero idling

MERGERS, VENTURES, ACQUISITIONS

GM cancels hydrogen plant plans

Linamar acquires Aludyne US assets

Archer buys Lilium’s patent portfolio

PRODUCTION DECREASE

GM pause triggers Vale project halt

PRODUCTION INCREASE

Renault-Geely boost hybrid engine output

Leapmotor to build EVs in Spain

Tesla increases Shanghai plant production

RAW MATERIAL DISRUPTION

China tightens rare earth exports

REGULATION

US-China tensions disrupt EV materials

RELOCATING

Judco moves HQ to North Carolina

SHUTDOWN

Stellantis delays Brampton plant decision

SUPPLY CHAIN

Nexperia seizure risks chip shortage

Bankruptcy

The US Trustee’s Office has joined creditors in calling for an independent investigation into bankrupt auto parts supplier First Brands Group.

The company says it cannot find $2.3B connected to off-balance sheet financing.

The watchdog pointed to serious allegations of fraud, dishonesty, incompetence, misconduct, or mismanagement and requested a quicker appointment of a bankruptcy examiner before the October 29 hearing.

First Brands, which filed for Chapter 11 in late September with over $10B in liabilities, is already being examined by financiers such as Jefferies, whose funds hold $715M in receivables related to the company.

The potential for fraud and missing funds increases financial risk for the auto parts supply chain and may delay payments to OEMs and Tier 1 suppliers connected to First Brands’ receivables network.

Closing

Europe’s automakers may need to close up to eight factories as weak demand and growing competition from Chinese brands, such as BYD and Chery, squeeze their capacity, according to AlixPartners.

Currently, European plants are operating at just 55% utilization, with Stellantis at 45%, which is far below the profitability level of roughly 250k units per year.

However, shutting down one major factory can cost approximately $1.75B and take up to three years due to labor resistance.

Meanwhile, BYD and Chery are expanding local production in Hungary, Turkey, and Spain. As a result, Chinese automakers could reach 10% European market share by 2030, accelerating the need for restructuring.

The anticipated restructuring could mean not only plant closures but also the consolidation of manufacturing operations, renegotiation of supplier contracts, and potential layoffs, which would have a profound impact on supplier networks and regional employment.

Disaster

The impact of last month’s fire at Novelis’ aluminum plant in Oswego, New York, is spreading across the industry.

As a result, Stellantis will shut down its Warren Truck Assembly Plant in Michigan for three weeks because of ongoing parts shortages.

Similarly, Ford is reducing production of its aluminum-bodied F-150 and has temporarily halted production of the F-150 Lightning.

Since Novelis’s hot mill will not restart until early 2026, automakers are still struggling to obtain enough aluminum to maintain steady production.

Expanding

Stellantis plans to invest $13B to expand its manufacturing operations in the United States, focusing on its plants in Belvidere, Illinois; Kokomo, Indiana; and Toledo, Ohio.

This investment will create approximately 5k new jobs and result in the reopening of the Belvidere plant for new Jeep production.

Stellantis aims to offset tariff costs, improve labor relations, and boost production of Jeep and utility vehicles with this investment.

Kia will allocate approximately $117M to build 100k EV2 and 80k EV4 models annually at its Slovakia plant by 2027, tripling European BEV output. The expansion supports EU zero-emission goals and secures Kia’s foothold in the small and compact EV segments.

Judd Wire, a subsidiary of Japan’s Sumitomo Electric Industries, opened a $32M production line in Aguascalientes, Mexico, to expand output of high-tech cables for EVs and hybrids, creating 40 jobs.

Human Capital

Webasto will eliminate approximately 300 jobs in Germany by year-end, primarily in administrative roles, to streamline operations and reduce costs.

The additional layoffs reflect the overall sustained pressure on Tier-1 suppliers to streamline operations as automakers shift spending toward EV technologies and cost control.

GM will keep 280 Detroit Factory Zero employees idled through year-end amid softening EV demand and the end of federal tax credits. Production of the Hummer EV and Escalade IQ is slowed, while Silverado EV output continues.

Mergers, Ventures, Acquisitions

GM has ended its next-generation hydrogen program and canceled plans for a $55M Detroit plant with Piston Automotive.

The company pointed to infrastructure challenges and uncertain policies as reasons for the decision. Now, GM will focus its engineering resources on developing electric vehicles, as interest in hydrogen projects declines.

Linamar will buy Aludyne’s North American assets for $300M, expanding its US casting and machining presence. The deal strengthens Linamar’s aluminum structures portfolio as automakers demand lighter, EV-compatible components.

Archer Aviation is acquiring 300 patents from its bankrupt competitor, Lilium, for $21M. This move will boost Archer’s propulsion and battery technology. The deal reflects accelerating consolidation across the cash-strained air-taxi sector.

Production Decrease

GM and POSCO’s decision to pause Phase 2 of their Ultium CAM plant led to Vale canceling its linked nickel sulfate project in Bécancour, Canada. These related setbacks underscore how global EV demand and cost pressures are hindering Quebec’s ambitions for battery production.

Production Increase

Renault and Geely’s Horse Powertrain partnership is increasing production of hybrid and traditional engines as demand for electric vehicles slows. This suggests that combustion engine technology will remain important in global supply chains for a longer time.

Currently, Horse produces over 8M engines and transmissions each year for more than 15 automakers, including Renault, Dacia, Volvo Cars, Nissan, Mitsubishi, and Mercedes-Benz.

Stellantis partner Leapmotor will begin production of its B10 electric SUV in Spain next year to avoid EU tariffs and expand its low-cost EV footprint in Europe.

Tesla is ramping up output at its Shanghai gigafactory in the fourth quarter. This follows a 2.8% rise in China-made sales in September, marking the end of a two-month decline. The company hopes this will boost momentum and support supply for both local and overseas markets.

Raw Material Disruption

China has tightened its export rules for rare earths, putting Europe’s auto industry at risk.

Italy’s auto parts group ANFIA says that with reserves running low, there is no longer a safety net against supply disruptions.

This shortage could slow down electric vehicle motor production and further increase Europe’s dependence on Chinese materials.

Regulation

Tensions between the US and China are escalating rapidly, and their impact is being felt across the global automotive industry, particularly in the realm of electric vehicles.

China plans to introduce new restrictions in November on rare earth metals and materials for lithium-ion batteries, which are vital for making EV motors and batteries.

At the same time, US President Trump has threatened, then eased up on, a new 100% tariff on goods from China.

China’s expanded restrictions will soon cover 12 out of 17 rare earth elements and will require export permits for many parts and tools used in battery manufacturing.

Experts say these steps could cause significant shortages, similar to the confusion that followed China’s earlier restrictions in April.

With tensions rising, US and European carmakers are now facing urgent challenges: securing the necessary materials may become more difficult and expensive, and they risk sudden disruptions to their production and sourcing plans.

Relocating

Judco Manufacturing will invest over $5M to relocate its headquarters and R&D hub to Snow Hill, North Carolina, adding 60 jobs. The expansion reinforces the state’s role in the reshoring of auto component production.

Shutdown

Stellantis informed Canadian Prime Minister Mark Carney that it’s seeking a new vehicle to build at its idled Brampton, Ontario, plant, but will make a decision only after a new US trade deal is finalized.

The Brampton plant, which had been shut since early 2024 for retooling, lost its planned Jeep Compass program to the Belvidere, Illinois, plant after Stellantis’ $13B US investment announcement. The delay adds pressure on Canada’s auto sector as Stellantis boosts output and jobs in the US.

Supply Chain

On September 30, the Dutch government seized control of chipmaker Nexperia to prevent the transfer of technology to its Chinese parent, Wingtech Technology, which is subject to US trade restrictions.

In response, China subsequently blocked exports from Nexperia’s Chinese plants.

Shortly after, the European Automobile Manufacturers Association (ACEA) warned that automakers could face “significant disruption” as Nexperia chips, though not high-tech, are essential and widely used across vehicles.

Volkswagen, BMW, Mercedes-Benz, and Stellantis have reported that, as of now, production remains unaffected, but they are reviewing risks and coordinating with suppliers, such as Bosch.

At the same time, Nexperia is in talks with Chinese authorities to obtain export exemptions.

Overall, the standoff exposes Europe’s reliance on China-based semiconductor assembly and could trigger another widespread production halt if Nexperia’s supply interruption continues.