Automotive Supply Chain Risk Digest #423

March 7 - 13, 2025, by Elm Analytics

Dear reader,

I honestly hope you’re hanging in there.

The latest MEMA survey underscores the turbulence we’re facing, and it’s eye-opening:

78% of suppliers are impacted by steel tariffs; 63% by aluminum

97% fear growing distress among sub-tier suppliers

78% lack sufficient U.S. capacity to replace globally sourced parts

These aren’t just statistics; they represent a very real threat to our supply chains—and to our ability to keep production moving.

In times of uncertainty, it’s easy to fall into the trap of “waiting and seeing.” However, this is our one chance to be proactive and get ahead of looming disruptions.

I’d be remiss not to mention that our supplyAware™ platform at Elm Analytics can help you stay ahead of these risks. It does three critical things:

Connects you to your suppliers for real-time data flow

Gathers essential insights to identify financial and operational risks

Empowers you to resolve problems before they escalate

Unlike many solutions out there, we’ve made a conscious choice to keep supplyAware™ accessibly priced for manufacturers of all sizes and quick to deploy.

While no one can fully prevent every tariff or capacity issue, having the proper visibility means you can catch trouble early and act before it becomes a crisis.

If you’d like to learn more about supplyAware™ or discuss whether it’s a fit for your organization, just let me know—leave your contact info, and we’ll get in touch.

Even a tiny step now can prevent major surprises down the road.

Warmly,

Nick Gaydos

Editor, Automotive Supply Chain Risk Digest

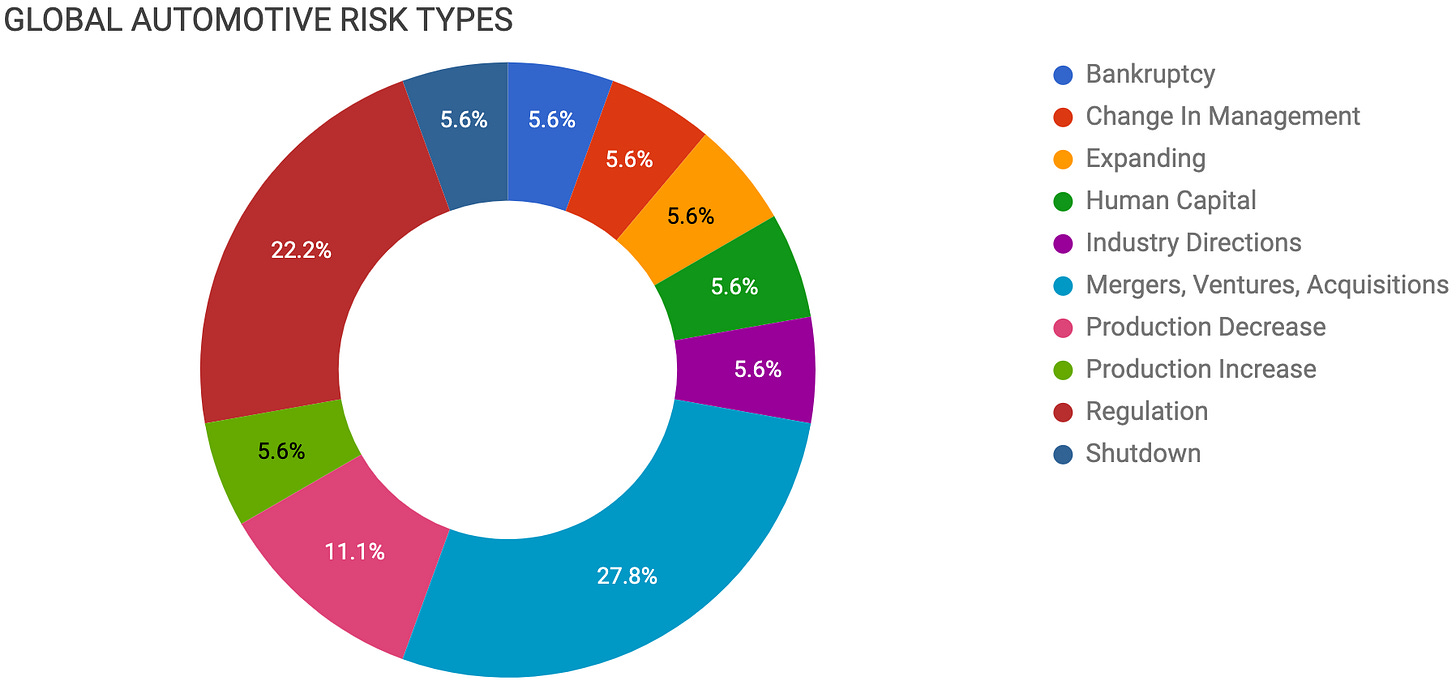

Contents

BANKRUPTCY

Northvolt AB files for bankruptcy

CHANGE IN MANAGEMENT

Nissan appoints Ivan Espinosa as CEO

EXPANDING

Samsung SDI raises funds for expansion

HUMAN CAPITAL

Thyssenkrupp cuts 1.8k jobs in auto unit

INDUSTRY DIRECTIONS

Mexico’s vehicle exports to US decline

MERGERS, VENTURES, ACQUISITIONS

Ford invests $4.8B in European restructuring

Altmin to build India’s first LFP plant

Sunwoda invests $1B in Thai EV plant

Tesla partners with Baidu for FSD in China

Hyundai to open hydrogen fuel cell plant

PRODUCTION DECREASE

VW cuts shifts in Tennessee due to low EV demand

Mercedes-Nissan Mexico JV faces uncertain future

PRODUCTION INCREASE

Toyota resumes RAV4 production after supply disruption

REGULATION

Tariffs on steel and aluminum raise costs

Trump’s steel tariffs escalate Canada trade tensions

US auto part tariffs create uncertainty

VW, BMW, Porsche respond to US tariffsz

SHUTDOWN

Jaguar Land Rover halts India EV plans

Bankruptcy

Northvolt AB has filed for bankruptcy in Sweden, citing rising capital costs, supply chain disruptions, and market shifts, but states that Northvolt North America remains solvent.

The fate of its Northvolt Six EV battery gigafactory near Montreal, Canada, which has $5B in government funding, remains uncertain. A court-appointed trustee and the company's lenders will determine the subsidiary's future and commitments, including plant construction, initially set to open in 2026.

Change In Management

Nissan has appointed Ivan Espinosa as its new CEO, effective April 1, amid declining earnings, market share losses, and internal instability. Espinosa, a company veteran, previously led global product strategy and EV planning.

His appointment follows failed merger talks with Honda and comes during rising competition from Chinese EV makers and potential US tariffs on Mexican-made vehicles.

This leadership change underscores Nissan's urgent need for a turnaround strategy to address challenges like slow EV adoption and trade uncertainties in North America.

Expanding

Samsung SDI has issued $1.38B in new shares and is using the proceeds to expand capacity at its factory in Hungary and invest in its JV with GM.

Human Capital

Thyssenkrupp will cut about 1.8k jobs $ in its Automotive Technology unit to save over $162.7m. The unit faced a 12% drop in order intake and a 10% decline in sales in Q1-2025, with earnings falling 75% to $13M. The company is also implementing a hiring freeze and reducing investments due to weak automotive demand and market uncertainties.

Industry Directions

Mexico's light vehicle exports to the US dropped 8% in January-February 2025, contributing to a 9.2% decline in February exports year-over-year. While production remained stable at 629,435 units (+0.40% YoY), major automakers like Volkswagen (-41.9%) and Stellantis (-46.1%) faced significant export declines.

In contrast, Toyota (+207%) and KIA (+25.1%) saw strong growth, while Nissan and Mazda boosted domestic sales despite falling exports. This decline highlights shifting trade dynamics and uneven performance among automakers in Mexico's role in North American vehicle supply chains.

Mergers, Ventures, Acquisitions

Ford is investing $4.8B to restructure its European business and reduce debt at its German subsidiary, Ford-Werke GmbH, as it struggles against rising competition from low-cost Chinese EVs.

The company has faced significant losses and previously announced plans to cut 4k jobs in Europe by 2027 to streamline operations. The funding will support Ford's multi-year transformation plan, including production at its Cologne plant, which builds the Explorer EV and Capri EV.

Altmin Private Limited will invest $87M to establish India's first Lithium Iron Phosphate (LFP) cathode giga-factory in Telangana, aiming to support domestic EV battery production with an initial capacity of 8GWh.

China's Sunwoda Electronic is set to invest over $1B in a new electric vehicle battery plant in Thailand to enhance the country's supply chain and support both domestic and export production of EVs.

Tesla is collaborating with Baidu to enhance its Full Self-Driving system in China, where local regulations limit the use of driving data for AI training. Baidu engineers are assisting in integrating high-precision mapping data into FSD Version 13 after customers criticized a recent update.

As competition from BYD and Xpeng rises, with their advanced driver assistance features offered without extra fees, Tesla must improve FSD to maintain its declining market share in China and comply with strict data laws.

Hyundai Motor will establish its first domestic hydrogen fuel cell plant in Ulsan, repurposing an idle transmission factory to integrate fuel cell production and vehicle assembly by 2028. Following its first hydrogen plant in Guangzhou, China, this move aligns with Hyundai's broader strategy to expand hydrogen technology, including the launch of the IniSiium hydrogen car.

Production Decrease

Volkswagen is reducing production at its Chattanooga, Tennessee, plant to two shifts due to lower EV demand, offering voluntary severance packages to affected workers. Additionally, the UAW has filed unfair labor practice charges against VW, accusing the company of anti-union behavior as contract negotiations continue following last year's unionization vote.

The future of COMPAS, the $1.4B Mercedes-Nissan JV in Aguascalientes, Mexico, is uncertain as both companies reevaluate ownership amid production declines. Nissan will halt Infiniti QX50 and QX55 production in December, while Mercedes plans to stop GLB production in early 2026, leaving the plant without assigned models $.

Nissan is considering a plug-in hybrid pickup for the facility, while Mercedes views it as a hedge against geopolitical risks. Complicating decisions are new Nissan leadership and potential US tariffs on Mexican imports. This uncertainty highlights broader challenges for global automaker alliances in adapting to shifting EV policies and trade tariffs.

Production Increase

Toyota resumed RAV4 production on March 13 after securing parts following a fatal explosion that disrupted supply chains at Chuo Spring Co in Toyota City, Japan. The March 6 blast, which killed one worker and injured two others, forced Toyota to suspend operations at two assembly plants in Japan for three and a half days. While production of the Harrier crossover has also resumed, one Daihatsu assembly line will remain suspended until at least March 17.

Regulation

With metal prices rising, the 25% tariffs on steel and aluminum $ that took effect on March 12 are expected to further increase costs for automakers and suppliers, even those sourcing domestically.

Removing previous trade exemptions for Canada, Mexico, and other allies complicates supply chains, pushing companies to find expensive and logistically challenging US suppliers.

Analysts caution that identifying new domestic sources can be delayed due to supply constraints, contracts, and regulatory approvals.

President Trump threatened to double tariffs to 50% on Canadian steel and aluminum before settling back after Ontario withdrew an electricity surcharge on US exports.

The move, part of escalating trade tensions, raised fears of Canadian retaliation and further tariffs on US auto imports, which Trump suggested could "shut down" Canada's auto industry.

The threat of auto tariffs and retaliatory measures adds instability to North America's integrated auto supply chain, increasing costs for manufacturers and consumers.

The lack of clear tariff rules for auto parts crossing US, Canadian, and Mexican borders creates unprecedented uncertainty for automakers and suppliers ahead of the April 2 implementation of Trump's 25% tariffs.

The removal of the drawback exemption, which previously prevented multiple tariffs on the same part, means components like pistons and crankshafts—which often move between countries multiple times—could now be taxed at each crossing.

However, it remains unclear whether tariffs apply to the entire component or just the added value, making accounting for these costs nearly impossible as companies struggle to determine their exposure and compliance strategies.

Volkswagen is developing contingency plans to address potential US tariffs on Mexican imports, while BMW has committed to absorbing additional costs rather than raising prices for now. VW's passenger car brand CEO ruled out shifting production from Mexico to the US in the short term, citing logistical challenges. Meanwhile, Porsche is evaluating price increases to offset potential 25% tariffs on European imports, and Stellantis is continuing with its plan to manufacture a midsize pickup in Illinois.

Shutdown

Jaguar Land Rover has halted plans to produce electric vehicles at Tata Motors' new $1B plant in southern India due to sourcing challenges and a decline in EV demand, which affects the launch of Tata's premium Avinya lineup. Initially projected to produce over 70k EVs, JLR's decision has prompted Tata to modify its designs and postpone the Avinya's launch to 2026-2027, highlighting ongoing supply chain issues in the EV market.