Automotive Supply Chain Risk Digest #404

October 25 - 31, 2024, by Elm Analytics

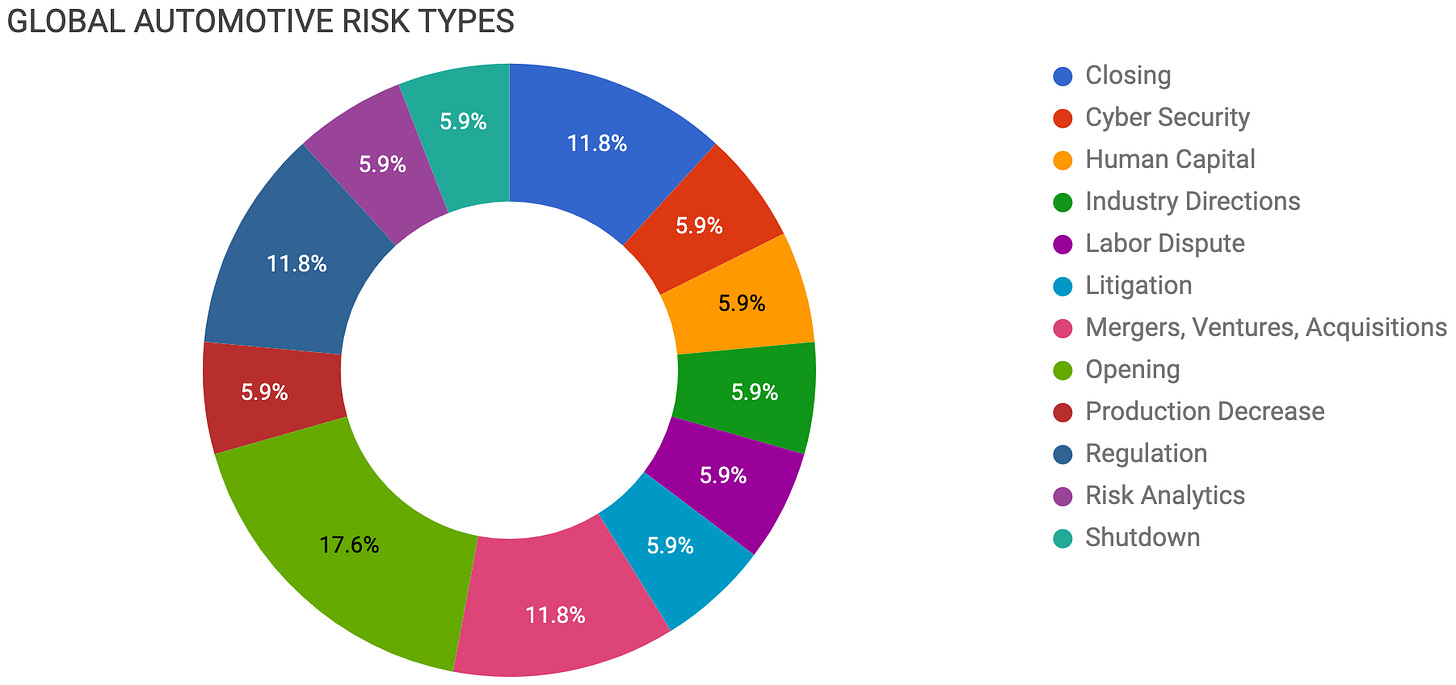

Contents

CLOSING

Volkswagen to close German plants amid competition pressures

Svolt Energy halts European operations due to slow EV market growth

CYBER SECURITY

Growing cybersecurity risks for connected vehicles

HUMAN CAPITAL

Sodecia Kansas City plant layoffs due to customer pause

INDUSTRY DIRECTIONS

Volkswagen loses ground in China amid price wars, human rights issues

LABOR DISPUTE

Canadian port strike could impact automotive supply chains

LITIGATION

Stellantis sues Brose for parts shipment dispute

MERGERS, VENTURES, ACQUISITIONS

Siemens acquires Altair for $10.6B to enhance software offerings

JSW and POSCO to build 5M tonnes steel plant in India

OPENING

Hanon Systems investing $155M in Ontario EV parts facility

Grand Topsun building $50M plant in Mexico

Seoyon E-hwa opens Texas plant for interior components

PRODUCTION DECREASE

Toyota sees first production decline in four years

REGULATION

EU imposes up to 45% tariffs on Chinese EVs

Spain strengthens China trade ties amid EU tariffs

RISK ANALYTICS

Foley report highlights regulatory and compliance challenges in automotive

SHUTDOWN

Ford pauses F-150 Lightning production amid losses

Closing

Volkswagen informed its employee council of plans to close at least three plants in Germany, with possible cuts affecting all German sites.

Daniela Cavallo, the head of VW's employee council, pledged to resist these moves, saying they would put "all German VW plants" at risk.

CEO Oliver Blume attributed the decision to increased competition from low-cost Chinese EVs, Germany's weakened manufacturing sector, and the need to maintain investment competitiveness.

Volkswagen also recently withdrew a long-standing job protection pledge that had barred layoffs through 2029, citing mounting financial pressures and its inability to achieve a €10B cost-saving target by 2026.

Plant closures and job cuts at Volkswagen's German sites underscore growing pressures on European automakers to adapt as they face fierce competition in the EV market and rising operational costs.

Svolt Energy, a Chinese battery maker spun out from Great Wall Motor, has announced the closure of its operations in Europe, specifically halting the development of two planned factories in Germany.

These facilities were intended to produce battery modules and packs in Saarland and battery cells in Brandenburg. The decision to terminate operations stems from the disappointing growth of the European EV market, which did not meet the company's expectations and financial capacity.

Cyber Security

With the rise of connected vehicles, cybersecurity risks have become a growing concern as OEMs race to adopt software-defined vehicles, aiming for projected revenue growth of up to $1.5T by 2030.

Vulnerabilities in automotive software and third-party applications expose OEMs and suppliers to cyber threats that evolve alongside new technology, according to cybersecurity attorney Samuel Goldstick.

Industry experts like Rocco Grillo emphasize the need for automakers to adopt an enterprise risk management approach to prepare for potential cyberattacks.

Recent high-profile attacks, such as the one on CDK Global, illustrate the costly disruptions that can impact OEMs, suppliers, and dealerships across the industry.

The automotive industry's growing reliance on software-defined systems increases exposure to cyber threats, necessitating more robust cybersecurity measures to protect the supply chain.

Human Capital

Germany's Sodecia Automotive plans to lay off 111 employees at its Kansas City, Missouri, facility due to a significant customer pausing part purchases, as detailed in a recent WARN filing.

While the layoffs are expected to begin on December 30 and may last less than six months, they could become permanent if the Kansas City facility closes.

Though Sodecia has not confirmed the customer's identity, General Motors, one of its key clients, is temporarily halting operations at its Fairfax Assembly Plant for a $391M retooling project to produce electric Chevrolet Bolts. This move has already spurred layoffs at multiple area suppliers.

Industry Directions

NY Times: How Volkswagen Lost Its Way in China

”A brutal price war, sudden shifts in consumer demand, and human rights issues in Xinjiang have left VW stumbling in a market it led for 40 years.”

Labor

The Canadian union representing foremen at British Columbia ports has issued a 72-hour strike notice, set to begin Monday, following stalled negotiations with employers. The BC Maritime Employers Association (BCMEA) claims the union rejected a final offer that included wage increases and a signing bonus.

This escalation could significantly disrupt port operations, impacting automotive supply chains that rely on timely shipments for parts and vehicles.

With the Vancouver port being the largest in Canada, any work stoppage could ripple through the West Coast logistics network, exacerbating delays in the already strained automotive market.

Litigation

Stellantis has filed a lawsuit against Brose North America, alleging the supplier shut down Windsor Assembly Plant operations and demanded price increases, costing the automaker over $3M in damages.

The legal dispute, which includes claims of breach of contract, stems from Brose's refusal to ship parts without a price hike, a tactic Stellantis argues is holding its operations "hostage."

This is the fifth supplier lawsuit Stellantis has pursued in a year $ as it confronts escalating costs across its supply chain. Brose has expressed hope for a resolution but noted that industry volatility has strained OEM-supplier relationships.

The lawsuit seeks financial restitution for past price increases paid by Stellantis under protest. The ongoing legal battles illustrate mounting tensions between OEMs and suppliers over cost pressures, posing risks to operational continuity within the automotive supply chain.

Mergers, Ventures, Acquisitions

Siemens acquired Altair Engineering $ for approximately $10.6B, with the deal expected to close in the second half of 2025.

This acquisition aims to enhance Siemens' software-driven product offerings and strengthen its digital platform, focusing on industrial AI and simulation capabilities.

Altair brings expertise in engineering software, high-performance computing, and data analytics, complementing Siemens' strengths in mechanical design. At the same time, the merger is expected to create new revenue through cross-selling and a combined global customer base.

Indian conglomerate JSW Group has partnered with South Korea's POSCO Group to establish a 5M tonnes per annum integrated steel plant in India. Beyond steel production, the agreement includes potential collaborations in battery materials for EVs and renewable energy.

Opening

South Korea's Hanon Systems, specializing in automotive thermal management for EVs, is investing over $155M to build a 284k sq ft facility in Woodbridge, Ontario.

This plant will produce e-compressors, a crucial component for EVs, marking North America's first dedicated e-compressor manufacturing site. Set to employ 300 workers, the facility is expected to produce up to 900k e-compressors annually to supply North American automakers.

Chinese automotive supplier Grand Topsun has launched the construction of its first manufacturing plant outside China in León, Guanajuato, with an investment of over $50M.

The new plant, located in the PILBA industrial park, will feature the world's most expansive electroplating line and specialize in plastic injection, stamping, plating, and assembly for major automakers, including GM, Mercedes-Benz, Volkswagen, and Tesla. The plant will be developed in two phases, with the first phase covering 226k sq ft slated for completion by early 2026, followed by a second 312k sq ft phase in 2027.

Seoyon E-hwa is building a new 200k sq ft interior components facility in Hutto, Texas, set to open in January. The facility will produce parts like door panels, bumpers, consults, seats, headliners, and rear parcel shelves and expects to supply nearby automakers like Tesla, Toyota, and GM.

Production Decrease

Toyota Motor Corp reported a 7% drop in global production for the April-September 2024 period, marking its first decline in four years.

The decrease, which totaled 4.71M vehicles, stemmed from weaker sales in China and a quality scandal that affected domestic production, including a halt on several models and a Prius recall. Production in China dropped sharply by 17.1% as Toyota faced intense competition from local EV manufacturers like BYD.

Despite these setbacks, Toyota's EV sales rose by 32.5%, although the company recently reduced its 2026 EV production target by 30% due to slowing demand. Meanwhile, total global output by Japan's eight major automakers also declined by 6%.

Regulation

The European Union's new tariffs of up to 45% on electric vehicles (EVs) made in China have gone into effect this week, aiming to shield European automakers from subsidized Chinese competition.

These tariffs vary based on subsidies each Chinese automaker received, with Tesla starting at 7.8% and SAIC Motor at 35.3%, to remain in effect for five years.

European automakers, particularly in Germany, have voiced concerns over potential retaliatory tariffs and long-term impacts on their business relationships in China.

Meanwhile, Chinese automakers, such as BYD, are responding by establishing production facilities within Europe to avoid tariffs, and the Chinese government is considering reciprocal tariffs on European imports.

This tariff policy reflects rising trade tensions that could disrupt the EV supply chain and escalate costs for European consumers while also pushing more Chinese manufacturers to establish European production bases.

Meanwhile, Spain has positioned itself as a "connector" country, fostering trade ties with China while abstaining from the European Union's vote on tariffs against Chinese electric vehicles.

Spain's strategy includes initiatives such as a new investment office in Catalonia for Chinese businesses, a $1 billion partnership with Envision Energy for a green hydrogen park, and deals with Chinese automakers like Chery to produce EVs locally.

Despite the broader EU tensions with China, the approach has attracted significant Chinese investment, with projects aimed at both green energy and automotive production in Spain.

Risk Analytics

Foley's 2024 End-to-End Manufacturing Manual (pdf) highlights crucial trends and challenges the automotive industry must navigate amidst evolving regulatory, legal, and technological landscapes.

Recent legal decisions have complicated traditional supply contracts, affecting the stability and pricing essential for automotive manufacturing.

Additionally, new environmental regulations, particularly around PFAS, are increasing compliance responsibilities.

As the industry integrates smart manufacturing and software-defined vehicles, there are heightened risks in data privacy, IP protection, and cybersecurity.

Finally, advancements in energy storage and stricter enforcement by agencies like the CPSC emphasize the need for rigorous compliance strategies to support safe, sustainable growth in the evolving automotive sector.

Shutdown

Ford announced it will idle production of its F-150 Lightning electric trucks at its Dearborn, Michigan plant until January 2025, with the last shift scheduled for November 15.

Ford cited a need to "adjust production for an optimal mix of sales growth and profitability" as it grapples with significant financial losses in its EV division, including a $1.2B loss in Q3 and a projected $5B loss for the year.

Although there was a great deal of initial excitement around the F-150 Lightning, Ford has faced price cuts, inventory issues, and growing competition from Tesla's Cybertruck, contributing to an uncertain path for its flagship electric truck.